Structural evaluation and materials testing

The Wolfson Unit MTIA has a long history in providing structural evaluation services to the marine industry. The variety of services offered includes failure investigations, finite element analysis, design support, expert witness and material characterisation tests. The Unit makes use of the existing testing and computational facilities at the University of Southampton but also works in collaboration with other institutes when required. The Unit is also actively involved in industrial research projects as part of its consultancy services.

Structural analysis

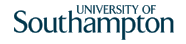

Structural analysis services are offered for marine and offshore applications. The Unit uses commercial FEA packages to perform structural analysis at global or component level. Linear and non-linear FEA can be performed for stress, buckling and ultimate strength analysis of ships, small craft and offshore structures made from homogeneous and composite materials or from sandwich construction. The University’s supercomputing facilities enable the numerical modelling of large complex structures at high level of detail even at global level.

Stress analysis of a 64m aluminium ketch

Typical examples of analytical capabilities include:

- Stress/strain analysis at global or component level.

- Linear eigenvalue analysis for definition of buckling loads.

- Large deflection and post-buckling analysis.

- Progressive failure and ultimate strength of structures.

- Composite material and sandwich panel failures.

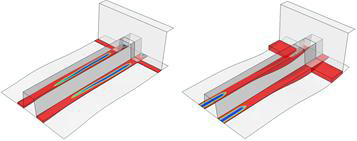

- Debonding of plate-stiffener, sandwich core-skin and composite patches.

- Geometric imperfections and boundary nonlinearities.

- Crack propagation under static and dynamic loads.

Failure Investigations

The Unit has undertaken numerous investigations into the causes of failure in sailing yacht masts and keels, sometimes in an expert witness capacity. These include failures due to structural defects, delamination, cracking and thermal problems.

CFRP mast failure investigation

Materials and Structures Testing

Testing facilities at the University of Southampton can be used for a wide variety of material and structural testing applications. Material characterisation in tension, compression, flexure and shear are performed with conventional testing machines. Large structural testing can be carried out for loads up to 1.5MN under static or dynamic loading of 100Hz maximum frequency. For more demanding load applications, the Unit collaborates with external institutes. Current facilities at the University also include environmental control (temperature, vacuum, humidity, aqueous environment), burn-off testing, ultrasonic scanning, strain measurement by laser shearography, and crack measurement.

Software

The Wolfson Unit has developed its own scantlings evaluation program HullScant for motor and sailing vessels under 24 metres. The program calculates the actual scantling structural properties of a vessel and can compare this with the requirements set out in the ISO standard 12215, Parts 5 and 8, which deal with pressures and scantling equations for fibre reinforced plastic, metal and wood monohull vessels and spade rudders. It has been developed in collaboration with the International Sailing Federation and Royal Yachting Association.

Plate-stiffening debonding failures in GRP hull construction